Welcome to the ZF 6HP19 and 6HP21 repair manual, your comprehensive guide for maintaining and repairing these advanced automatic transmissions. This manual provides detailed procedures, troubleshooting tips, and essential information to ensure proper functionality and longevity of your transmission. Designed for both DIY enthusiasts and professional mechanics, it covers everything from fluid checks to complex mechatronic unit repairs. Follow the instructions carefully to achieve optimal results and avoid costly mistakes.

Overview of the ZF 6HP19 and 6HP21 Transmissions

The ZF 6HP19 and 6HP21 are advanced 6-speed automatic transmissions designed for a wide range of vehicles. Known for their smooth shifting and efficient performance, these units feature cutting-edge technology, including adaptive control systems and mechatronic integration. The 6HP19 is compact and lightweight, ideal for smaller vehicles, while the 6HP21 is slightly larger, offering higher torque capacity for larger engines. Both transmissions are praised for their fuel efficiency, reliability, and seamless operation. Understanding their design and functionality is crucial for proper maintenance and repair, ensuring optimal performance and extending their lifespan.

Importance of the Repair Manual for Proper Maintenance

A repair manual is essential for maintaining the ZF 6HP19 and 6HP21 transmissions. It provides step-by-step instructions, ensuring repairs are done correctly and safely. Without it, diagnosing issues becomes challenging, leading to potential misrepairs. The manual covers fluid checks, solenoid replacements, and mechatronic updates, critical for optimal performance. It also includes torque specifications and alignment procedures, preventing further damage. By following the manual, technicians can avoid costly errors and extend the transmission’s lifespan. Regular maintenance, as outlined, ensures smooth operation, making the repair manual an indispensable resource for professionals and enthusiasts alike.

Key Components of the ZF 6HP19 and 6HP21

The ZF 6HP19 and 6HP21 transmissions consist of key components like the torque converter, gear sets, valve body, mechatronic unit, and solenoid pack, ensuring smooth gear shifts and optimal performance.

Understanding the Valve Body and Solenoids

The valve body is a critical component that controls fluid flow and pressure within the transmission, ensuring smooth gear transitions. Solenoids, such as the EDS3 solenoid, are electro-hydraulic actuators that regulate the valve body’s operation. They are responsible for opening and closing valves to direct transmission fluid to the appropriate clutch packs or bands. Proper solenoid function is essential for maintaining transmission performance. If solenoids malfunction, symptoms like erratic shifting or failure to engage gears may occur. Regular inspection and replacement of worn solenoids are crucial for preventing transmission damage. Always refer to the repair manual for specific solenoid locations and replacement procedures.

Role of the Mechatronic Unit in Transmission Functionality

The mechatronic unit is the control center of the ZF 6HP19 and 6HP21 transmissions, responsible for managing gear shifts, pressure regulation, and clutch engagement. It integrates software and hardware to ensure smooth transmission operation. The unit communicates with the vehicle’s ECU, monitoring sensors like speed, temperature, and throttle position. Proper mechatronic function is crucial for adaptive shifting, fuel efficiency, and performance. If the mechatronic unit fails, the transmission may exhibit erratic behavior or fail to shift gears. After repairs, an adaptation drive and TCU software reset are essential to recalibrate the system. Always use the correct software version and follow manual instructions for reprogramming and testing.

Fluid Capacity and Type Recommendations

The ZF 6HP19 and 6HP21 transmissions require the use of ZF LifeguardFluid 6 synthetic transmission fluid for optimal performance and longevity. The total fluid capacity is approximately 9 liters, depending on the vehicle application; Always check the fluid level when the transmission is at operating temperature (between 30°C and 35°C) for accurate readings. Use a high-quality filter during fluid changes to prevent contamination. Ensure the fluid meets ZF specifications, as incorrect fluid can damage internal components. Refer to the repair manual for specific filling instructions and guidelines to avoid overfilling or underfilling the system.

Pre-Repair Checks and Preparations

Ensure the transmission fluid level and temperature are within specified ranges. Hoist the vehicle horizontally and use proper equipment for safe repair preparation. Inspect for leaks or damage before starting work.

Transmission Fluid Level and Temperature Checks

Before starting any repair, ensure the transmission fluid temperature is between 30°C and 35°C for accurate level measurement. Use a scan tool or test equipment to monitor temperature. Place the vehicle on a level surface and engage park or neutral gear. Check the fluid level using the dipstick, ensuring it aligns with the “FULL” mark. Top up with ZF LifeguardFluid 6 if necessary. Avoid overfilling, as this can damage the transmission. Always refer to the manual for specific instructions and safety precautions. Proper fluid level and temperature ensure reliable transmission operation and prevent premature wear. This step is critical for accurate diagnostics and repair success.

Tools and Equipment Required for Repair Work

To effectively repair the ZF 6HP19 and 6HP21 transmissions, you’ll need a variety of tools and equipment. Essential items include a scan tool for monitoring transmission fluid temperature and level, ensuring accurate diagnostics. Lint-free clothes are recommended when handling components like the valve body to prevent damage. Specialized software or diagnostic tools are necessary for tasks such as resetting the TCU software and performing adaptation drives. A car lift or hoist is crucial for safely elevating the vehicle during repair. Additionally, standard mechanical tools like wrenches and screwdrivers are required for disassembly and inspection. Finally, ensure you have ZF LifeguardFluid 6 on hand for proper fluid replacement, along with the necessary equipment for filling and draining the transmission fluid. These tools and equipment are vital for a successful repair process.

Repair Procedures

The repair process involves systematic disassembly, inspection, and replacement of worn or damaged parts. Use specialized tools and follow detailed guidelines to ensure reliability and performance.

Disassembly and Inspection of the Transmission

Before disassembling the ZF 6HP19 or 6HP21 transmission, ensure the vehicle is securely lifted and all necessary safety precautions are in place. Begin by draining the transmission fluid and disconnecting electrical connectors. Remove the transmission pan and filter, then carefully take out the valve body and solenoid pack. Inspect each component for wear or damage, paying particular attention to clutch packs, bearings, and seals. Use a torque wrench to remove the main shaft and countershaft, taking note of any shims or spacers. Document all findings to guide the replacement process effectively.

Replacement of Worn or Damaged Parts

When replacing worn or damaged parts in the ZF 6HP19 or 6HP21 transmission, ensure all components are thoroughly cleaned and inspected. Replace clutch packs, bearings, and seals with genuine ZF parts or OEM equivalents. Use a press to install new bearings and seals, applying a thin layer of lubricant to prevent premature wear. Reinstall the valve body and solenoid pack, ensuring proper alignment and connection of electrical connectors. Replace the transmission filter and pan gasket, then refill with the recommended ZF LifeguardFluid 6. After reassembly, perform a test drive to verify smooth operation and check for leaks or unusual noises.

Reassembly and Alignment of Components

Reassembly of the ZF 6HP19 and 6HP21 transmission requires precision to ensure proper alignment and functionality. Begin by carefully reinstalling the gear sets, ensuring they are properly seated and aligned; Use a torque wrench to tighten bolts to ZF-specified torque values. Reattach the valve body, ensuring it is securely fastened and all electrical connectors are properly aligned. Reinstall the mechatronic unit, making sure it is correctly seated and connected. Finally, replace the oil pan and filter, and refill the transmission with the recommended ZF LifeguardFluid 6. Double-check all connections and alignments before closing the transmission case.

Post-Repair Testing and Troubleshooting

Conduct a test drive to ensure smooth gear transitions and proper transmission functionality. Check for leaks, unusual noises, or erratic behavior. Use diagnostic tools to monitor TCU communication and reset adaptive learning if necessary. Address any issues promptly to prevent further damage.

Adaptation Drive and TCU Software Reset

After completing repairs, perform an adaptation drive to recalibrate the transmission’s adaptive learning. Ensure the vehicle is on a level surface and the transmission fluid is at the recommended level. Use diagnostic tools to reset the TCU software and clear any fault codes. Drive the vehicle under various conditions, including city driving and highway speeds, to allow the system to relearn shifting patterns. Monitor the transmission’s performance during this process. If issues persist, refer to the diagnostic trouble codes and repeat the adaptation drive as needed. Proper reset ensures smooth operation and prevents premature wear on components.

Common Issues and Diagnostic Tips

Common issues with the ZF 6HP19 and 6HP21 include erratic shifting, slipping gears, and delayed engagement. These problems often stem from worn solenoids, faulty mechatronic units, or low transmission fluid levels. To diagnose, use a diagnostic tool to check for fault codes, such as P0750 or P1765, which indicate solenoid malfunctions. Inspect the valve body for deposits and clean or replace it if necessary. Verify fluid levels and condition, as contaminated or low fluid can mimic electronic faults. For persistent issues, perform an adaptation drive and reset the TCU software. Always refer to the repair manual for detailed troubleshooting procedures and solutions.

Additional Resources

Access the official ZF repair manual PDF for detailed instructions and diagrams. Supplementary guides, including visual aids and troubleshooting tips, are available for download from authorized ZF websites.

Accessing the PDF Instruction Manual

To access the ZF 6HP19 and 6HP21 repair manual in PDF format, visit the official ZF website or authorized transmission repair portals. The manual provides detailed step-by-step instructions, diagrams, and specifications for fluid capacity, valve body repairs, and mechatronic unit replacements. Ensure you download the latest version compatible with your transmission model. Additional resources, such as troubleshooting guides and visual diagrams, are often included to assist with complex repairs. Always verify the source for authenticity to avoid incorrect or outdated information. This manual is essential for ensuring accurate and safe repairs, making it a vital tool for both professionals and enthusiasts.

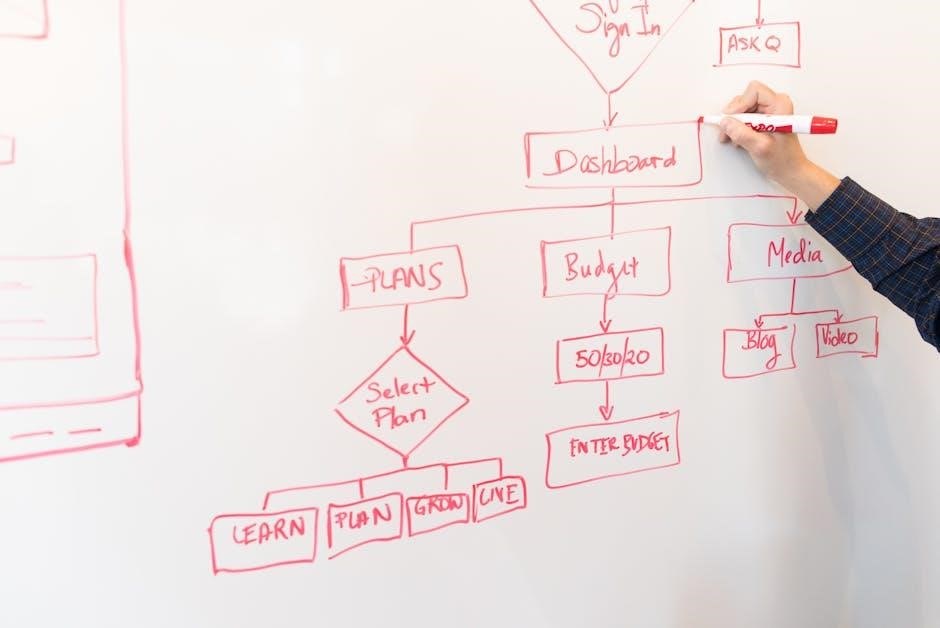

Visual Guides and Diagrams for Reference

The ZF 6HP19 and 6HP21 repair manual includes detailed visual guides and diagrams to assist with complex repair procedures. These resources provide clear illustrations of components like the valve body, solenoids, and mechatronic units, helping technicians understand their locations and functions. Diagrams for fluid capacity, torque specifications, and wiring connections are also included. High-resolution images of the transmission’s internal structure and step-by-step disassembly guides are invaluable for precise repairs. These visual aids ensure accuracy and reduce the risk of errors during maintenance or overhaul. Referencing these diagrams alongside the written instructions is essential for achieving professional-grade results.

The ZF 6HP19 and 6HP21 repair manual serves as an essential resource for technicians and enthusiasts alike, providing detailed guidance for maintaining and repairing these sophisticated transmissions. By following the outlined procedures, troubleshooting tips, and visual references, users can ensure optimal performance and longevity of their vehicles. Proper adherence to fluid specifications, mechatronic unit care, and post-repair testing is crucial for achieving reliable results. This manual underscores the importance of precision and safety in transmission work, making it an indispensable tool for anyone tackling repairs on these advanced systems. Referencing the PDF guide and diagrams will further enhance your repair experience.